Whatsapp:+86-18638891360sales@fv-bearing.com

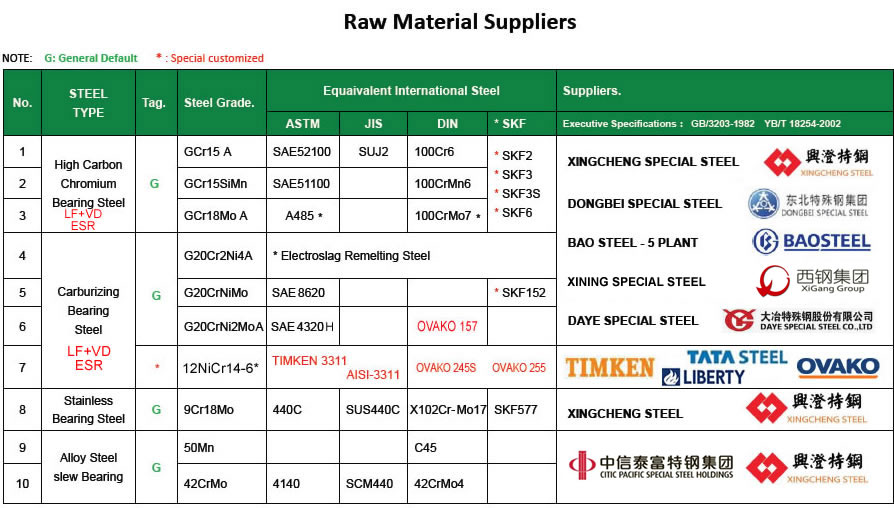

The choice of raw materials for the bearing directly affects the performance and working life of the bearing. The selection of materials needs to meet the working environment of the bearing. The rings and rolling elements of the bearing not only bear greater stress, but also have good wear resistance and dimensional stability. Therefore, the purity of the steel used to manufacture the bearing is very high. FV bearings usually use vacuum degassed steel (VIM, VAR) or electroslag remelted steel (ESR).

There are usually several kinds of materials for manufacturing bearings:

1. High-carbon chromium alloy steel. (Chromium, Mn, Molybdenum,Si,Carbon Steel)

2. Carburized steel. (Chromium, Nickel, Molybdenum,Tungsten, Low Carbon Steel)

3. High temperature bearing steel. (High-speed steel)

4. Stainless steel. (404 ,304 Food grade stainless steel )

5. Induction heating hardened steel (C45, 50Mn, 42CrMo steel etc.)

6. Other materials (Aluminum alloy, resin plastic, ceramics, etc.)

Tel:+86-186 3793 0086

Fax:+86 379 6290 1536

Mail:sales@fv-bearing.com